JMC PAPER TECH P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JMC PAPER TECH P LTD.

Pulper With Belt Conveyor

Description / Specification of Pulper With Belt Conveyor

We are involved in offering a wide range of Pulper With Belt Conveyor to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pulper With Belt Conveyor. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

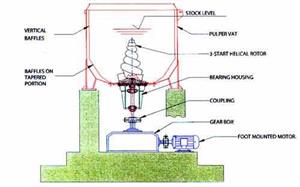

High Consistency Pulper Gear Box Drive

Description / Specification of High Consistency Pulper Gear Box Drive

We are involved in offering a wide range of High Consistency Pulper Gear Box Drive to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of High Consistency Pulper Gear Box Drive. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

High Density Cleaner

Description / Specification of High Density Cleaner

We are involved in offering a wide range of High Density Cleaner to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of High Density Cleaner. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Turbo Separator

Salient Features

- Effective separation of heavy and light impurities.

- Minimum fiber loss.

- Easy Maintenance

- The body is made out of Stainless Steel with base frame and stiffeners in Mild Steel. Economy model is fabricated totally in Mild Steel with 55 cladding in the feed chamber.

- A force Vortex is formed in the Separator by the 5.5, rotor. The heavy particles are carried outward by Centrifugal force in to the junk trap. The rotor and Screen are designed to slush paper chips and remove all the non fibrous material which goes out as light reject and further treated in secondary separator or Johnson Screen.

- The accept stock passes through the screen fitted behind the rotor.

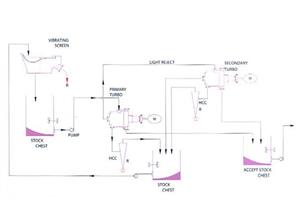

Turbo With Extended Cleansing System

Salient Features

- Most Efficient system for Kraft and Board Mills

- Two Stage Turbo and Cleaner make quality pulp

- Operating Consistency 3-4%

- HCC with Auto reject Discharge System

- Suitable system above Plant Capacity

- Turbo with Cylindrical Body and perforated screen Plate

J. M. C Medium Consistency Screen

The ideal screen for waste paper stock preparation (white and brown grade). The special rotor design allows the screen to operate at 3 -4.5% consistency. The stock suspension is screened through a screen drum having perforation or slot

Salient Features

- JMC offers gland or mechanical seal (option) arrangement.

- Complete 55-304 construction.

- Efficient separation of contaminants.

- Low power consumption.

- Exceptional improvement in screening efficiency.

- Improve quality of paper.

- Dependable paper machine operation.

- Excellent manufacturing fitness.

- Easy change over of Belt and pulleys in minimum time.

- Heavy & sturdy construction.

Baskets Perforated Or Slotted Step Rotor

Description / Specification of Baskets Perforated Or Slotted Step Rotor

We are involved in offering a wide range of Baskets Perforated Or Slotted Step Rotor to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Baskets Perforated Or Slotted Step Rotor. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

J. M. C. Low Consistency Screen

Description / Specification of J. M. C. Low Consistency Screen

We are involved in offering a wide range of J. M. C. Low Consistency Screen to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of J. M. C. Low Consistency Screen. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Baskets Perforated Or Slotted Foil Rotor

Description / Specification of Baskets Perforated Or Slotted Foil Rotor

We are involved in offering a wide range of Baskets Perforated Or Slotted Foil Rotor to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Baskets Perforated Or Slotted Foil Rotor. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Centricleaners

Salient Features

- Effective removal of Sand, unbeaten paper chips hard Cooked fibers and other no fibrous heavy materials

- Low fiber rejection

- Low Pressure drop

- Fabricated from SS 304 and 316 Material

- Intel Tapered Headers with pulp valve in SS construction

- Available in 500 and 1000 LPM throughput

- Fibber recovery arrangement in Last Stage

Stock Chest Agitators

Energy efficient agitators find application in all type of Pulp storage chests, including Hight Density Towers, Mixing Chest & Machine Chest.

The sturdy design incorporate Bearings & Glands. Located outside, optimally designed adjustable propeller blades. All parts coming in contact with stock made of stainless Steel, the agitators are highly energy efficient and have the provision for adjusting the vane angle to suit specific process requirement of gentle or strong agitation.

Stock Thickener

Salient Features

- Decker Thickener compressing of CI/SS Moulds and MS/ SS Vat, are best suited for removal of excess water from stock

- Sizes vary from 2.00 mtrs to 3.00 mtrs depending upon the process capacity

- Input Consistency 1% out put consistency of 4%

- Minimum fiber loss due to modified cum washing purpose

- Constructed in SS 304 and SS 316 Material

- Driven with Variable Speed drive for setting the drainage of different of stock

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.